At a Glance

The customer is a global company that specialises in delivering innovative business solutions in structures and logistics including workforce housing, innovative modular facilities, construction, site support services, and logistics and operations management.

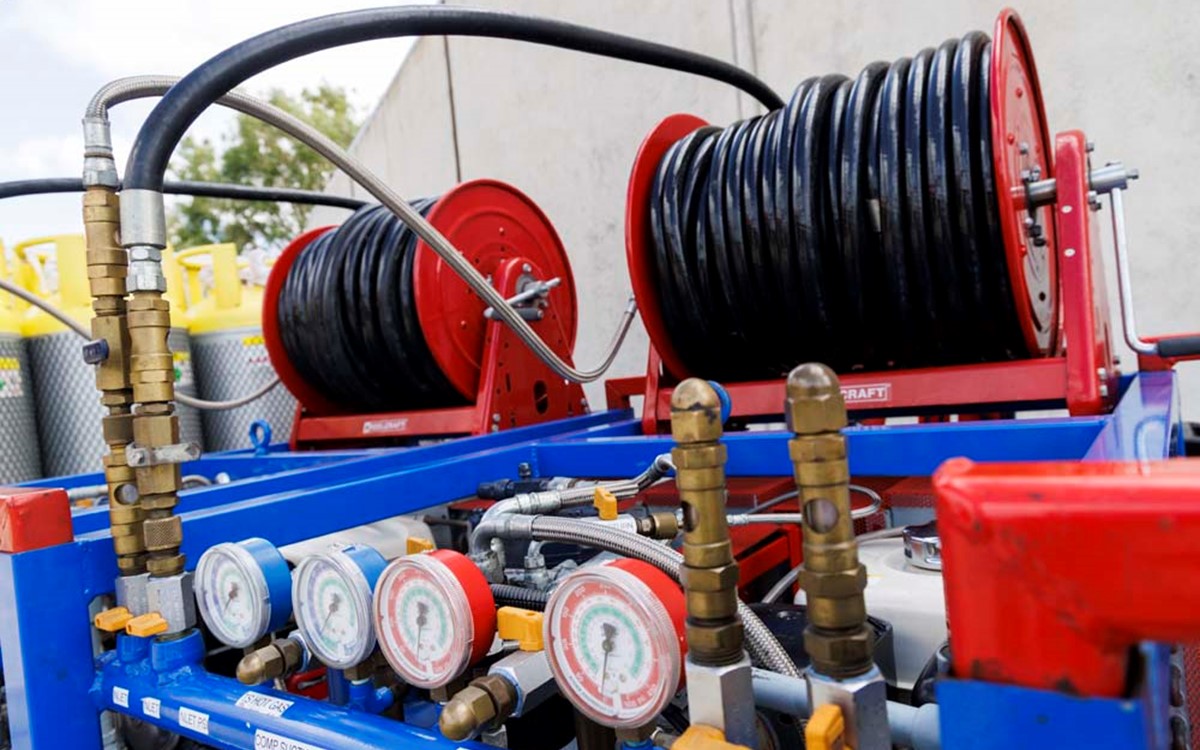

At the completion of construction projects, the client collects and manages decommissioned equipment, such as air conditioning units and white goods from temporary construction site offices. The client needed to quickly process the decommissioned equipment for recycling and disposal to recover costs, as well as to prevent potential refrigerant gas leaks into the atmosphere.

Challenges

- Efficiently manage large quantities of decommissioned equipment from construction site offices to recover costs and enable recycling and/or disposal

- Avoid refrigerant leaks into atmosphere from decommissioned equipment

Benefits

- Environmental: Over 50 tonnes of C0 equivalent was avoided by safely removing refrigerant.

- Operational Efficiency: Project was completed in half the time of traditional recovery machines allowing client to process equipment for disposal and recycling.

When we’re recovering refrigerant from a large amount of units, staging equipment side by side allows us to connect and recover up to 5 units at a time, saving time and costs for the client. We can recover so much faster than traditional recovery methods.

Read the Full Case Study

Over 50 tonnes of CO equivalent was avoided by safely removing refrigerant gas from decommissioned construction site equipment.